Spokes should be a certain tension in order to support the bike and your weight. Too tight and they can snap, so how tight should spokes be?

When your spokes are too loose they rattle and they have no strength to keep the wheels or bike up. When they are too tight, they can snap or bend under the pressure.

Each type of bike will require a different spoke tension depending on their purpose. It is important to know what this tension is so you can prevent the spokes from being too tight.

The recommended tension for spokes on bicycle wheels is between 80 Kilograms force (KGF) and 230 Kilograms force, depending on the type of bike you have. The general rule is that you want to set the spoke tension as high as the weakest part of the wheel which is the rim.

There are tools such as spoke tension meters to help you determine if your spokes are too tight.

Knowing how tight your bike’s spokes should be will be the difference between riding the roads or a collapsed wheel and you hitting the road.

Recommended Gear

To see all of my up-to-date recommendations for bikes and cycling gear, check out this resource that I made for you!

Table of Contents

How Tight Should Spokes Be On A BMX or Mountain Bike

BMX and mountain bikes are built tough. You ride a BMX aggressively and hard and you perform tricks and stunts. And mountain bikes are headed out over all types of terrain taking on bumps, holes, and rocks.

In order for the bike to handle this it needs to be secure. The tightness of the spokes plays a big role in this. Spokes on these bikes that are too tight can buckle under the pressure.

Your weight plus the jumps, curbs, and bounces can easily damage an overly tight spoke.

On a BMX and mountain bike, you want a couple of millimeters movement in the spokes when you squeeze them together.

Spokes that are too tight will not easily squeeze in this way. Often spokes that are overly tight on one side lead to loose spokes on the opposite side, so make sure you check all spokes.

To tighten any they turn counterclockwise, and to loosen spokes, turn them clockwise.

Move around the wheel making sure they are all at the same tension to prevent buckling.

How Tight Should Spokes Be On A Road Bike

Spokes on a road bike are also important because the wheels are thinner and therefore under more pressure.

They are more susceptible to bumps in the road and at high speeds, this can damage a tire or wheel if the spokes are too tight.

There needs to be enough tension to keep the wheel stable and solid so there is no chance of buckling as you ride along.

However, too loose and the wheel will not stand up to even the best paved street.

The spokes on a road bike should feel tight and firm. The spokes need to give a little when you give them a hard squeeze. But they should give.

If they are not moving at all, they are too tight. Check the spokes all around the rim in this way. Tighten any that are too loose (give too much when you squeeze them).

Do not turn the spoke itself. Turn the nipple holding the spoke to the rim. Counter-clockwise will tighten the spoke.

Do not over tighten them. Any spies that are too tight, will need to be loosened until they give a little when squeezed.

What Tension Should Spokes Be

Wheels that are well-built will not need to have the spokes adjusted often. If you are going to be adjusting spokes, remember to loosen the opposite side spokes as you tighten one side.

Spokes will ideally feel firm and tight. You do not want spokes to feel loose or move easily when squeezed.

It is rare for spokes to be too tight, but this can happen if you are not taking care when adjusting loose spokes.

That being said, it is more common for the spokes on the freewheel side of the rear wheel to be tighter than the others. So be sure to check those more often and loosen as needed.

The recommended tension for spokes on bicycle wheels will be between 80 kilograms force (KGF) and 230 Kilograms force, depending on the type of bike you have.

The general rule is that you want to set the spoke tension as high as the weakest part of the wheel which is the rim.

Wheels that are well-built will not need to have the spokes adjusted often. If you are going to be adjusting spokes, remember to loosen the opposite side spokes as you tighten one side.

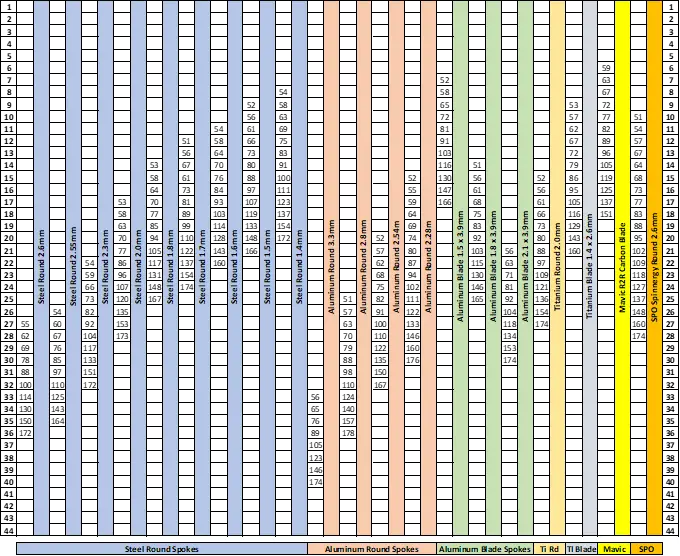

Spoke Tension Chart

The spoke tension chart below will help you confirm if your bike is good to go.

Using a tension meter, you can verify the KGF rating and make sure it is in line with the recommended tension for the type of bike you have.

In general, a heavier and stronger rim such as those on a mountain or BMX bike will handle more tension, closer to the 230 KGF. Lighter rims such as those on racing or road bikes will need much lower tension.

For conversion purposes, remember that 1KGF is equal to 10 Newtons or 2.2 pounds of force. This means a 100 KGF reading is the same as 1000 Newtons or 220 pounds force on the rim.

How To Tighten Spokes

Loose spokes are just as dangerous as overly tight spokes. To get them back to a normal and safe tension is known as truing.

Knowing the correct way to tighten a spoke is the best way to prevent over tightening. This is easy to do, so it is important to check spokes after tightening to make sure you have not gone too far.

Spoke Tension Meter

Spoke tension meters are an efficient way to check the poke tension.

Simply hold the tension meter horizontally and squeeze the handle, placing the spoke between the posts. Then release the handles and check the reading on the scale.

Be sure to measure the tension of all spokes, completing one side at a time. All will have close to the same tension reading but will not be exact.

If you get a difference of 20% between spokes, this is perfectly acceptable

Spoke Wrench

A spoke wrench is another tool you can use to adjust spoke tension. This small wrench grips the spoke nipples so you can tighten or loosen the spokes to align your wheel.

The wrenches come in different sizes, so be sure to match the wrench size to the nipple size of your spokes.

You will have to turn the bike upside down and rest it on the handlebars and seat.

Truing the wheel or adjusting spoke tension involves turning the right nipples the right amount. You want to get all spokes to be of similar tension.

Using the wrench to tighten or loosen spokes, you can check that you do not adjust the same spoke twice by putting a piece of tape on them.

Only turn the spokes in small increments and spin the wheel to check your progress as you go.

The most common mistake is turning a nipple in the wrong direction which is why double checking is essential.

How To Tighten Bike Spokes Without A Spoke Wrench

If you do not have a spoke wrench and are musically inclined, you can check spoke tension using your fingers.

Clucking the spokes is easy and all you have to do is listen to the noise they make. Loose spokes will make a dull sound while an overly tight spoke will make an obvious “twang” sound.

While this is not the most accurate method, you can check spoke tension this way and make adjustments to keep you safe on the road.

Then when you are back home, get them checked with a tension meter and wrench. Without the spoke wrench, you can tighten spokes with a flathead screwdriver.

Can You Over Tighten Spokes

It is very easy to over tighten spokes. If you simply just turn the spoke (or nipple) until it feels tight or turn it as far as it will go with a spoke wrench, it may be too tight.

It is important to check the tension after each time you tighten a spoke. This way if it is too tight, you can loosen it before riding.

Final Thoughts

The spokes on your bike need to be tight. Without the proper tension, they cannot support the wheel, the bike, or your weight.

The wheel will buckle without spoke tension. Too much tension can also be dangerous.

So how tight should spokes be? They need to be tight giving a little bit of movement when squeezed hard.

More than this is too loose. No movement is too tight. To keep your wheels rolling, check spoke tension and follow recommended tension readings for the bike you have.